CCT | Cylindrically-conical beer fermentation tanks CLASSIC : technical parameters

Technical parameters of cylindrical-conical beer fermentation tanks

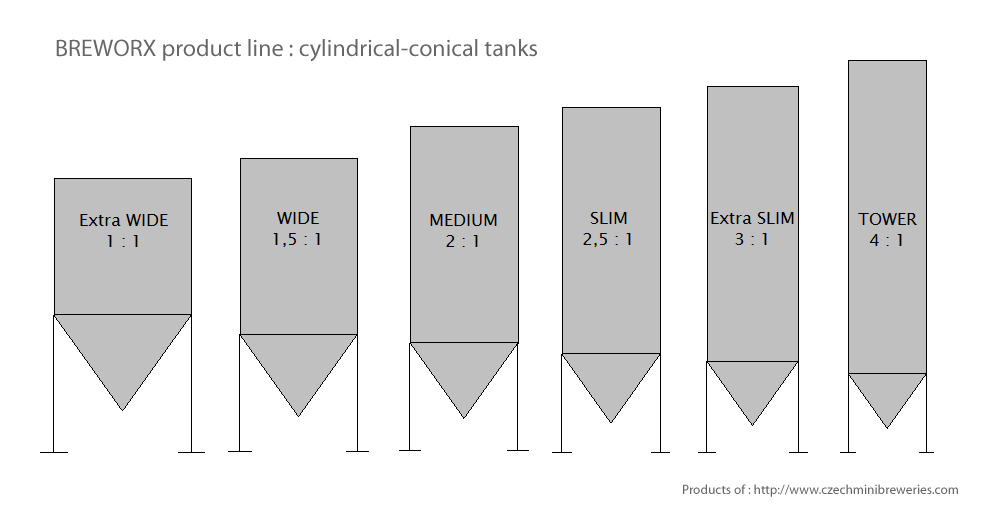

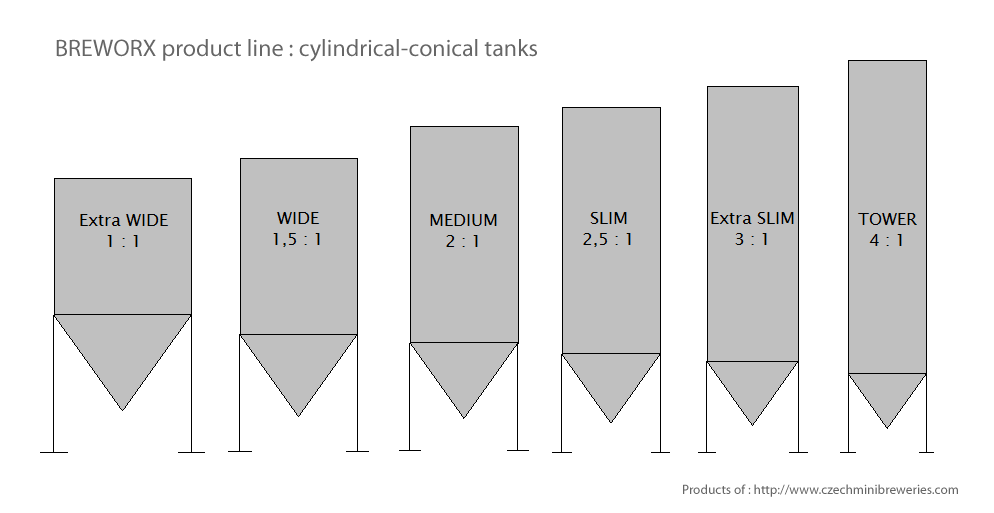

Produced variants of cylindrical-conical fermentation tanks

Cylindroconical fermentation tanks are made of stainless food steel DIN 1.4301.

We know from experiences that the requirements of customers ordered cylindrical-conical tanks are significantly different. Therefore, there is not only one solution CC tanks, but a customer can choose from several dimensional and structural variants.

Fermentation and maturation cylindrical-conical tanks cooled by water (or glycol)

I. CCTM modular cylindrical-conical tanks (standard = with PUR insulation, including outer stailess steel jacket)

Modular fermenters with universal use and many customizable configurations

- Two variations according the maximal overpressure : 0.5 bar / 3.0 bar

- Three variations according the quality class : SQ – standard quality / HQ – high quality / TQ – top quality

- Five recommended configurations

II. CCT tanks classic (standard = with PUR insulation, including outer stailess steel jacket)

- Two variations according the maximal overpressure : 0.0 bar / 3.0 bar

- Six variations according the dimensions ratio : Extra Wide / Wide / Medium / Slim / Extra Slim / Tower

- Two variations according the quality class : SQ – standard quality / HQ – high quality

III. FUIC fermentation units : the fermentation and maturation units MODULO with the integrated compact water cooler

- FUIC-SNP-2xCCT : Fermentation units with 2pcs of simplified CCTs for maximal overpressure 0.0 bar

- FUIC-SLP-2xCCT : Fermentation-maturation units with 2pcs of simplified CCTs for maximal overpressure 1.5 bar

- FUIC-SHP-2xCCT : Fermentation-maturation units with 2pcs of simplified CCTs for maximal overpressure 3.0 bar

- FUIC 2xCCT : Fermentation-maturation units with 2pcs of classical CCTs for maximal overpressure 0.0 – 3.0 bar

Fermentation cylindrical conical tanks without insulation – cooled by air

IV. CC tanks simplified (standard = without insulation, for surcharge = with insulation without outer stailess steel jacket)

- CCT-SNP : CC tanks simplified equipped for maximal overpressure 0.0 bar

- CCT-SLP : CC tanks simplified equipped for maximal overpressure 1.5 bar

- CCT-SHP : CC tanks simplified equipped for maximal overpressure 3.0 bar

V. Nano-CCT : Micro CC tanks without insulation, without cooling channels, for homebrewing

Specifické technické parametry pro individuální požadavky zákazníků

I. Dimensional variations of beer fermentation tanks:

We produce fermentation tanks in 6 production lines by the ratio of the height and diameter of the container. It is advantage for customers, because dimensions of tanks is often necessary to adapt for limited space dispositions.

Depending on the size of the tank can be ordered fermentation tanks of useful volume from 1.5 hectoliters to 80 hectoliters.

II. Variants beer fermentation tanks by pressure limit :

In addition, the customer can choose between the pressure and non-pressure containers. According to the maximum allowable pressure in the vessel we produce CC fermentation tanks in several designs:

- Non-pressure fermentation tanks – the maximum available overpressure is 0.5 bar – it is designed as 2.0 bar tank, but it is not declared as pressure tank and doesn´t have a pressure vessel passport. Suitable for non-pressure fermentation of beer or cider.

- Low-pressure fermentation tanks – the maximum available overpressure is 1.5 bar (including PED certificate for pressure vessels) – an adequate solution of the majority of microbreweries for fermentation and maturation of beer and also for drafting of beer or cider.

- High-pressure fermentation tanks – the maximum available overpressure is 3.0 bar (according to specific customer requirements up to 5.0 bar), includes PED certificate for pressure vessels – container can be used not only for the fermentation and maturation of beer, but also as pressure bright beer tank for tapping into kegs or bottles, filtration and drafting of beer or cider.

III. Variants beer fermentation tanks by isolation :

- Isolated fermentation tanks for unconditioned spaces – tanks containing one or more chilled zones in the cylindrical and conical part (according to the height of the tank). The cylindrical and conical parts are insulated with polyurethane foam.

- Non-isolated fermentation tanks for air-cooling space – tanks containing one or more chilled zones in the cylindrical and conical part (according to the height of the tank). The cylindrical and conical parts are not insulated. It is assumed the location of the tank in the air cooling room.

We provide insulation of smaller fermentation tanks in the factory during their production. We mount the isolation foam and jacket to larger tanks in the site to avoid damage during transport.

IV. Variants beer fermentation tanks by the quality of workmanship finish :

According to requirements and financial possibilities of customers we produce fermentation tanks at three classes of quality:

- HQ – HIGH Quality – High quality workmanship of all parts, welded joints and surfaces. The outer surface is unified. All functional armatures and fittings that have an impact on the reliability and safety of the products are made in Europe or in the USA. This construction is standard and is used in the majority of large and small professional breweries. Perfectly smooth inner surface is needed for perfect separation of the used yeast from the beer or cider, especially at single-phase fermentation of beer or cider when the both fermentation and maturation process are provided in the same CC tank.

- SQ – STANDARD Quality – The inner surface of the container is cut to Ra 1.6, weld seams are stained, the outer surface is not unified. Many small breweries use this solution because investment savings. The inner surface allows sufficient separation of sedimented yeast from beverage. It requires a longer period of sanitation, greater consumption of sanitizing solution and hot water. It can be used for both single-phase and two-phase fermentation of beverages.

- LQ – LOWER Quality – The inner surface of the container is not cuted, weld seams are stained, the outer surface is not unified. Many small breweries use this solution because investment savings. Requires a longer period of sanitation, greater consumption of sanitizing solutions and hot water. These tanks can be used for two-phase fermentation beer or cider, which the fermentation is provided in other tank than the maturation of beer or cider.

Typical equipment of fermentation tanks

- Cooling channels – duplicators for circulating of coolant

- PUR insulation – thickness corresponding to the size of the tank and the environment

- Stainless steel jacket – with the customer selected surface finishing

- Manhole on the top cone or on cylinder part (according to customer requirements)

- Outlet / inlet for beer

- Outlet / inlet for dosing and discharge of yeast

- Sanitation shower – sprayball (static or rotary)

- Sampling cock

- Upstream mechanism from 0 to 1.5 bar

- Safety valve

- Airline valve to pressurize the container

- Thermometer

- Manometer

- Level indicator

Optional equipment for fermentation tanks

- Upstream mechanism from 0 to 3 bar (hi-pressure combi tanks with bottling function)

- Automatic valves for metering the coolant into the cooling channels

- Local thermostat unit (control valves duplicators, depending on the temperature)

- Control system for automatic control of fermentation and maturation process

- Carbonation stone – the special jet for carbonation of beverages from CO2 bottles

Parameters of fermentation tanks in a typical equipment :

NEW – Buy the CC tanks simply in our