BREWORX CLASSIC | Technical specification of the wort brew machine

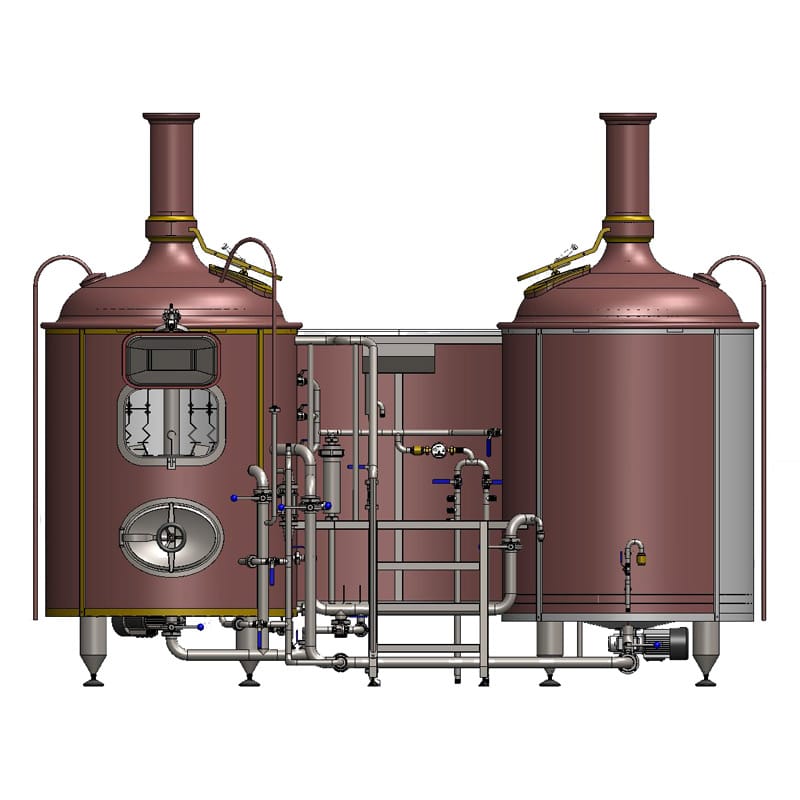

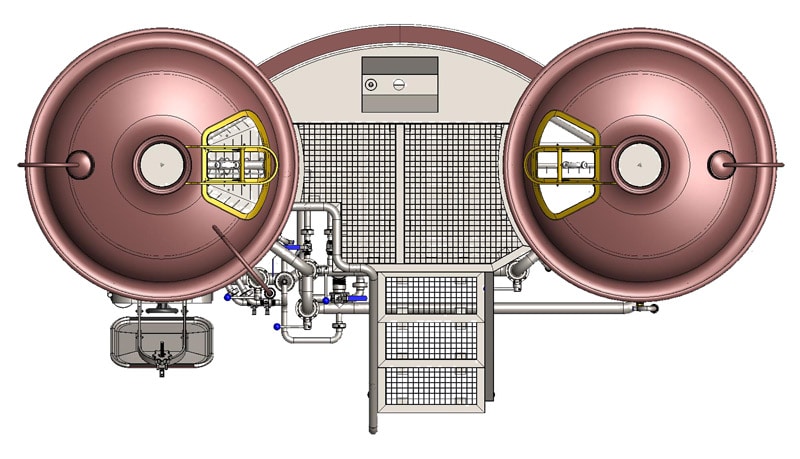

A typical feature of luxury interior restaurant microbrewery BREWORX Classic is an interior two-vessel or three-vessel brewhouse which includes mash tun, lauter tun and whirlpool integrated into frame with wort cooler, steps, laboratory sink and Control Panel. The brewhouse is available in several design variants.

A typical feature of luxury interior restaurant microbrewery BREWORX Classic is an interior two-vessel or three-vessel brewhouse which includes mash tun, lauter tun and whirlpool integrated into frame with wort cooler, steps, laboratory sink and Control Panel. The brewhouse is available in several design variants.

Brewhouse BREWORX CLASSIC – the beer production from traditional ingredients

Construction of the brewhouse BREWORX Classic allows production of all known types of beers by Czech and foreign recipes, from traditional ingredients (malt, hops, water and yeast), by an infusion and decoction method. If necessary, it is possible to prepare the wort in the brewhouse from concentrate (like in Brewhouses LiteME and LiteWC). Unlike most foreign products our brewhouse is optimized for the production of high-quality bottom-fermented lager beer (pilsner type), or it can be used for brewing any other top-fermented beers.

The volume of the daily brewhouse production is two wort batches in 24 hours.

Available models of the BREWORX CLASSIC brewhouses

Microbreweries BREWORX CLASSIC are delivered with a volume of brewhouse capacity 1.5 HL – 20 HL. Total annual production of the microbrewery is then given by the brewing schedule, number and type of fermentation and maturation vessels, number and type of serving tanks, selected range of beer types and other parameters.

- BH-BWCL-600 : BREWORX CLASSIC 600 liters : Wort brew machine / Brewhouse

The wort production machine (brewhouse ) BREWORX CLASSIC 600 is a compact food machine which includes all necessary equipment to produce 708 liters of wort (it is an optimal volume for production approximately 600 liters of beer) in one brew batch from malt (or malt extract or wort concentrate), hops and drinking water. The BREWORX CLASSIC is a three-tank equipment, some tanks have more functions : 1st tank = mashing tank (tank to mixing malt in water) + wort boiling tank (tank to boiling of wort), 2nd tank = wort filtration tank (tank to filtration of wort) + 3rd tank… Read more »

The wort production machine (brewhouse ) BREWORX CLASSIC 600 is a compact food machine which includes all necessary equipment to produce 708 liters of wort (it is an optimal volume for production approximately 600 liters of beer) in one brew batch from malt (or malt extract or wort concentrate), hops and drinking water. The BREWORX CLASSIC is a three-tank equipment, some tanks have more functions : 1st tank = mashing tank (tank to mixing malt in water) + wort boiling tank (tank to boiling of wort), 2nd tank = wort filtration tank (tank to filtration of wort) + 3rd tank… Read more » - BH-BWCL-300 : BREWORX CLASSIC 300 liters : Wort brew machine / Brewhouse

The wort production machine (brewhouse ) BREWORX CLASSIC 300 is a compact food machine which includes all necessary equipment to produce 354 liters of wort (it is an optimal volume for production approximately 300 liters of beer) in one brew batch from malt (or malt extract or wort concentrate), hops and drinking water. The BREWORX CLASSIC is a three-tank equipment, some tanks have more functions : 1st tank = mashing tank (tank to mixing malt in water) + wort boiling tank (tank to boiling of wort), 2nd tank = wort filtration tank (tank to filtration of wort) + 3rd tank… Read more »

The wort production machine (brewhouse ) BREWORX CLASSIC 300 is a compact food machine which includes all necessary equipment to produce 354 liters of wort (it is an optimal volume for production approximately 300 liters of beer) in one brew batch from malt (or malt extract or wort concentrate), hops and drinking water. The BREWORX CLASSIC is a three-tank equipment, some tanks have more functions : 1st tank = mashing tank (tank to mixing malt in water) + wort boiling tank (tank to boiling of wort), 2nd tank = wort filtration tank (tank to filtration of wort) + 3rd tank… Read more » - BH-BWCL-1000 : BREWORX CLASSIC 1000 liters : Wort brew machine / Brewhouse

The wort production machine (brewhouse ) BREWORX CLASSIC 1000 is a compact food machine which includes all necessary equipment to produce 1180 liters of wort (it is an optimal volume for production approximately 1000 liters of beer) in one brew batch from malt (or malt extract or wort concentrate), hops and drinking water. The BREWORX CLASSIC is a three-tank equipment, some tanks have more functions : 1st tank = mashing tank (tank to mixing malt in water) + wort boiling tank (tank to boiling of wort), 2nd tank = wort filtration tank (tank to filtration of wort) + 3rd tank… Read more »

The wort production machine (brewhouse ) BREWORX CLASSIC 1000 is a compact food machine which includes all necessary equipment to produce 1180 liters of wort (it is an optimal volume for production approximately 1000 liters of beer) in one brew batch from malt (or malt extract or wort concentrate), hops and drinking water. The BREWORX CLASSIC is a three-tank equipment, some tanks have more functions : 1st tank = mashing tank (tank to mixing malt in water) + wort boiling tank (tank to boiling of wort), 2nd tank = wort filtration tank (tank to filtration of wort) + 3rd tank… Read more » - BH-BWCL-2000 : BREWORX CLASSIC 2000 liters : Wort brew machine / Brewhouse

The wort production machine (brewhouse ) BREWORX CLASSIC 2000 is a compact food machine which includes all necessary equipment to produce 2360 liters of wort (it is an optimal volume for production approximately 2000 liters of beer) in one brew batch from malt (or malt extract or wort concentrate), hops and drinking water. The BREWORX CLASSIC is a three-tank equipment, some tanks have more functions : 1st tank = mashing tank (tank to mixing malt in water) + wort boiling tank (tank to boiling of wort), 2nd tank = wort filtration tank (tank to filtration of wort) + 3rd tank… Read more »

The wort production machine (brewhouse ) BREWORX CLASSIC 2000 is a compact food machine which includes all necessary equipment to produce 2360 liters of wort (it is an optimal volume for production approximately 2000 liters of beer) in one brew batch from malt (or malt extract or wort concentrate), hops and drinking water. The BREWORX CLASSIC is a three-tank equipment, some tanks have more functions : 1st tank = mashing tank (tank to mixing malt in water) + wort boiling tank (tank to boiling of wort), 2nd tank = wort filtration tank (tank to filtration of wort) + 3rd tank… Read more » - BH-BWCL-1500 : BREWORX CLASSIC 1500 liters : Wort brew machine / Brewhouse

The wort production machine (brewhouse ) BREWORX CLASSIC 1500 is a compact food machine which includes all necessary equipment to produce 1770 liters of wort (it is an optimal volume for production approximately 1500 liters of beer) in one brew batch from malt (or malt extract or wort concentrate), hops and drinking water. The BREWORX CLASSIC is a three-tank equipment, some tanks have more functions : 1st tank = mashing tank (tank to mixing malt in water) + wort boiling tank (tank to boiling of wort), 2nd tank = wort filtration tank (tank to filtration of wort) + 3rd tank… Read more »

The wort production machine (brewhouse ) BREWORX CLASSIC 1500 is a compact food machine which includes all necessary equipment to produce 1770 liters of wort (it is an optimal volume for production approximately 1500 liters of beer) in one brew batch from malt (or malt extract or wort concentrate), hops and drinking water. The BREWORX CLASSIC is a three-tank equipment, some tanks have more functions : 1st tank = mashing tank (tank to mixing malt in water) + wort boiling tank (tank to boiling of wort), 2nd tank = wort filtration tank (tank to filtration of wort) + 3rd tank… Read more »

Brewhouse description :

The brewhouse is the main part of each brewery. It is a food machine whose primary function is the production of beer wort. The wort is an intermediate product. The next phase of the production cycle is fermentation and maturation of wort. This raises the final product – beer.

Design of the BREWORX CLASSIC brewhouse

Two design variations : with copper hats and coat, with a polished stainless steel finish

The singleblock BREWORX CLASSIC brewhouse is a compact food machine which includes all necessary equipment to produce 150-2000 liters (it depends on brewhouse type) of beer wort in one batch. It is three-vessels brewhouse wherein two containers are integrated into one cylinder (three separated tanks are available for the brewhouse Breworx Classic 1000-2000). This we have achieved full functionality brewing while we retained the traditional design of the Czech type brewhouse which is ideal for producing of world-famous Czech type beer. However, this brewhouse is fully capable for manufacturing all types of beer, which is produced anywhere in the world.

The brewhouse includes three vessels : mashing-wort boiling kettle, lautering tun, whirlpool (is usable also for collection lautered wort before wort boiling). The lautering tun and whirlpool tank are superposed, so the brewhouse looks like two-vessel machine. It is better because this design saves space in an interior. All three vessels are fixed on common frame and they are easy accessable from an central platform or from rear side of the brewhouse.

The patented design of the brewhouse allows partially to manufacture of two batches of wort simultaneously – a new batch can be mashed immediately after wort boiling while performing whirling of the wort and unloading of a previous batch (it is valid only for version brewhouse with two pumps). This makes it possible to produce two to four doses wort during one day (24 hours) – depending on the type brewhouse and brewing method from 150 to 8000 liters of wort per day.

It is possible to produce wort either infusion or decoction way. Control system of the brewhouse is either semi-automatic or fully automatic – two available versions.

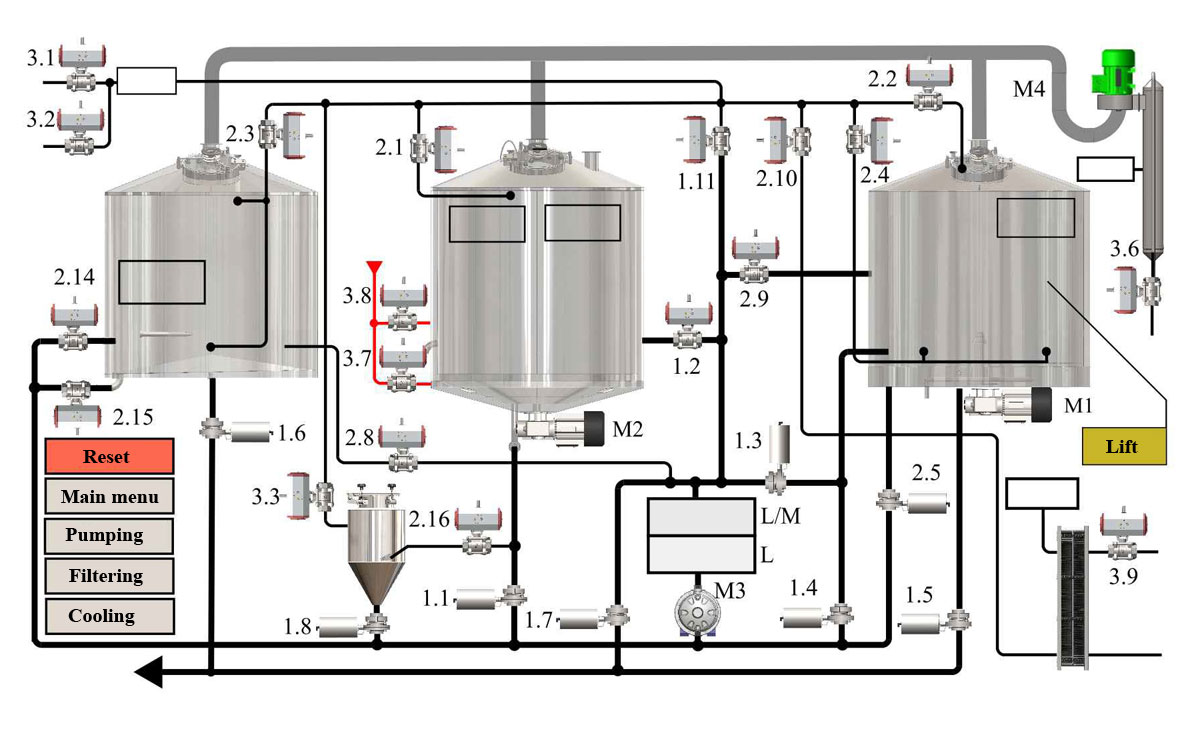

The brewhouse BREWORX CLASSIC includes in standard :

- mash tun – kettel for boiling

- lauter tun – for filtering

- whirlpool – for separation of hop dregs from wort

- laboratory sink

- control panel

- platform with steps

- all pipes and wires connections

- all mechanically or automatically controlled valves and armatures

- electric switchboard cabinet

- control computer

Why to choose the BREWORX CLASSIC ?

Main advantages of the BREWORX CLASSIC compared with brewhouses of other manufacturers:

- The BREWORX CLASSSIC is a compact standardized wort machine, which is based on a common frame. The brewhouse is easily transportable in one unit, or it can be broken down into 3 smaller parts.

- Our brewhouse allows the production of almost all types of beers, which are known in Europe and the USA. The BREWORX CLASSIC brewhouse allows the production of beer using both infusion or decoction method.

- The whirlpool is integrated under the lauter tun. This solution saves space in the brewery (only for brewhouse volumes lower than 1000 liters)

- The dosage of the raw materials is carried out at the beginning of the brewing process. Brewer does not need to intervene in the brewing process (only automatic version).

- Two options of wort lautering – gravitational (first phase) and by pump (second phase).

- The electrical switchgear and the control computer are integrated in the body of the brew house. This solution greatly eliminates the required amount of electrical wiring and electrical work on site.

- An elimination of the negative influence of water conductivity on beer quality using the deionization belt.

- The brewhouse construction allows you to start mashing of the second batch during a last phase of the first batch – it speeds up the double brewing process. (It is valid only for version brewhouse with two pumps)

- The highly efficient heating system of the brewhouse depends on the choosed variation :

- Indirect steam heating of the brewhouse dramatically accelerates the wort production process. A hot steam is supplied in the brewhouse from an external electric, gas or pellet steam generator. Due to heat transfer from the steam to the heated product using a big heat transfer area the beer is not locally overheated. This is prevention particularly in beer production completely prevented so. Caramelisation malt, which is undesirable localized heat malt mash (ie. The work), in which the malt mash mashing chars on the walls of the boiler and hence to the formation of carcinogenic substances and spáleninových flavored beer.

- The placement of the lower engine agitator under the bottom of the brewhouse prevents dripping of grease into the brewhouse.

- Easy access to all controls and flaps.

- The unique glass single-hand doors on both tanks. Overpressure manholes may not be opened during wort production, while a slight overpressure in the brewhouse accelerates the brewing process.

- Exactly calculated sizes of containers to minimize oxidation of wort.

- An automatic ejection of waste grains.

- Removable segment sieve with trapezoidal holes allows the perfect lautering of wort. High load capacity of the sieve

- The possibility of producing beer from barley malt and wheat malt. The brewhouse allows also production beer from malt extract or wort concentrate.

Options and properties

Two raw materials for production of beer wort :

- Classical raw materials : Malt + hops + drinking water + brewer’s yeast + (optionally other ingrediences)

- Beer concentrates : Malt extract + hops + drinking water + brewer’s yeast + (optionally other ingrediences)

Four production capacities of the brewhouse :

- 150-2000 liters of beer wort per day – one batch for 12 hour – source raw materials are malt or malt extract, hops, drinking water and brewer’s yeast

- 300-4000 liters of beer wort per day – two batches for 24 hour – source raw materials are malt or malt extract, hops, drinking water and brewer’s yeast

- 450-6000 liters of beer wort per day – three batches for 12 hour – source raw materials are malt extract, hops, drinking water and brewer’s yeast

- 600-8000 liters of beer wort per day – four batches for 24 hour – source raw materials are malt extract, hops, drinking water and brewer’s yeast

Two available designs :

- SD – Stainless steel design – all vessels are fully made of stainless steel AISI 304

- CD – Copper design – all main parts are made of stainless steel AISI 304, only outer sheath and hats of containers are made of copper.

Two available heating systems :

- EH – Electric heating – the heating of kettel is performed by electric heating elements without the use of heat transfer fluid

- SH – Steam heating – the heating of kettel is performed by hot steam produced by steam generator. Heating by hot steam significantly speeds up the boiling process and it is better for the heated wort (no caramelization of malt). This system requires a connection of the brewhouse to electric, gas or pellet steam generator that is not included in the brewhouse (see an optional accessories).

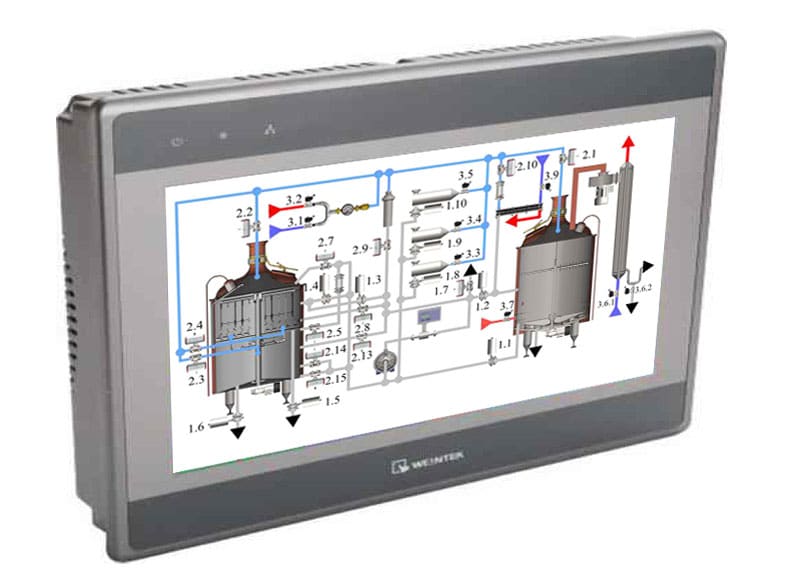

Two available control systems :

- MC – Manual control – – the brewhouse is manually operated with the support of computer application that guides the user step by step through the production process. Heating of the brewhouse, stirrer speed, the pump running are controlled from a central control panel.

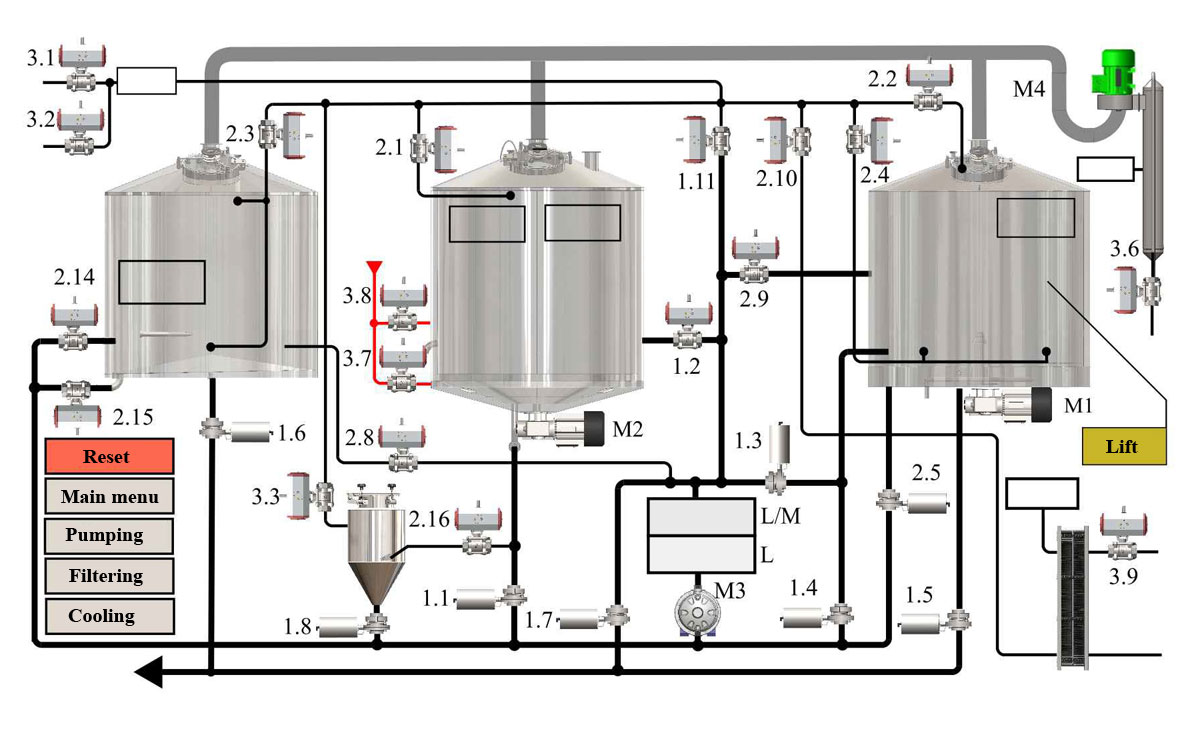

- AC – Automatic control – automatically controlled brewhouse supported by industrial computer which automatically controls the production of wort and requires little user´s interaction. Features such as heating of the brewhouse, stirrer speed, pumps running, valves and control valves are computer controlled and adjusted to a central control panel with touchscreen.

Why choose AC system for brewing control ? Main reasons are :

- Elimination of human errors – machine accurately and timely perform necessary tasks

- Costs saving for owner – only one worker is necessary for manipulating in the brewery

- Minimize the number of error conditions in the brewery – everything is still under control

- Monitoring and registration of the production process into the computer memory

- Minimization of requirements for constant operator attention – early reaction of machine

- Stable quality of beer – standard manufacturing procedures are always observed

- Six pre-programmed recipes – for production of the most known types of beer : Pils, Lager, Black, Weissenbeer, Ale, Special

- Manual brewing mode – for production of all other types of beer

- Special sanitation mode – for automatic cleaning,sanitizing and sterilization of the brewhouse, wort pipes, armatures and other brewery equipment

Recommendation :

We emphatically recommend choose the automatic brewhouse control system for this type of brewhouse and also the automatic control system for media and fermentation & maturation process !

The computer brewhouse automatic control system always ensures the right brewing operations timing without damaged wort batches.

The automatic control system for media and fermentation & maturation process allows automatic monitoring and controlling of the most important parts of beer fermentation and maturation process (from 1 to 30 tanks max) and operations with media.

How looks the automatic control panel ? This is a main menu. Choose one from several beer types or functions then click and go.

Special functions :

- CIP function – the special mode ensures cleaning, sanitization and sterilization of the brewhouse, wort pipes and optionally also other devices in the brewery

Technical specification

(Example values – valid for the Breworx Classic 600 brewhouse)

Mash tun – kettle

- Usable capacity 1 275 L

- Dimensions Ø 1 240 mm, height 1 500 mm

- Steam bottom area 0.94 m2

- Steam jacketing area 0.36 m2

- Steam valve ASCOjucomatik DN 20

- Steam condensate discharge DN 20

- Four-arm agitator with gearbox output power 118 Nm, input power 0.55 kW

- Lighting 12V 35W

- 1x Sanitary rotating shower DN 25

- Steamer DN 100, 3x spraying device

- Insulation 50 mm plasticized cotton,

- external jacketing copper 1 mm (only for CD – Copper Design version)

- Top cover in copper + steamer imitation DN 200 (only for CD – Copper Design version)

- Measuring rod with ČMI-cz certification/directive 71/316/EEC

Lauter tun – filter tank

- Usable capacity 673 L

- Dimensions Ø 1 240 mm, height 660 mm

- Filtration bottom 6 segments with 12% permeability

- Nozzles for rinsing under wire 3 pc

- Stirrer 2 arms, 8 blades

- Gearbox 640 Nm, input power 2200W

- Lighting 12V 35W

- Mechanical temperature indicator 0-120ºC stainless steel

- 1x Sanitary rotating shower DN 25

- Three-way setting valve with sight glass DN 50

- Brewer’s grains discharge 420*540

- Equipment for automatic grains discharge

- Insulation 50 mm plasticized cotton,

- external jacketing copper 1 mm (only for CD – Copper Design version)

- Top cover in copper + steamer imitation DN 200 (only for CD – Copper Design version)

Whirlpool tun – swirl tank

- Usable capacity 765 l

- Dimensions Ø 1 240 mm, height 750 mm

- Sanitary manhole 430*340 mm

- 1x Sanitary rotating shower DN 25

- Tangential nozzle DN 20

- Level indicator DN 20

- Fermenting valve 2x DN 25

- Insulation 50 mm plasticized cotton,

- External jacketing copper 1 mm (only for CD – Copper Design version)

Piping, armatures

- Primary line DN 50, 5x flap valve DN 50

- Drain line DN 50, 3x flap valve DN 50

- Sanitary line DN 25, 4x valve DN 25

- Water supply and additional lines DN 25, 5x valve DN 25

- Beer wort filter 2000l/h/DN 80

- Mashing /fermentation pump DWO 150 Ebara

- Input power 750W

- H max. 2,2 bar

- pump controlled by frequency converter Fronic 1,5 kW

Electric installation

- Main switch 3x25A with central stop button

- Motor starter 3×2,5-4A

- 1x Frequency converter Fronic mini 1,5 kW

- 2x Frequency converter Fronic mini 0,75 kW

- Digital temperature regulator of mash kettle Dixel XR20D

- Digital regulator of beer wort output temperature Dixel XR20D

- Circuit breaker 6A 230V

- Circuit breaker 10A 230V

- Circuit breaker 4A 230V

- Plastic DIN switchboard, 36 modules

- Wiring

- 5*1,5 18 m

- 5*2,5 10 m

- 3*1 48 m

Dimensions and weight

- Weight 980 kg

- Basic size minimum height 2 800 mm

- Width 3 800 mm

- Depth 2 030 mm

This boiling equipment is mounted in a rigid frame made of 1.4301, 8 pc adjustable supports installed in its bottom part.

Connections:

- Beer wort discharge DN 25

- Cold water supply DN 25

- Hot water supply DN 25

- Drain line DN 50

- Electro 5*2,5 4800 W

Auxiliaries:

- Wash basin with combined lever taps assembly

- Cooling device for samples

- Flow meter DN 25 of water supply

- Water filter

- Combined water taps assembly with digital indication of temperatures

- Steps to service bridge 750*730*585 mm

Transport

This equipment is usually shipped in assembled state with exception for copper covers, steamer for steam condensation, steps of service bridge and electric switchboard.

Optional accessories

- ACS – Automatic control system – automatic brewing process of wort fully controlles by computer

- STG – Steam generator – necessary only for version with SH heating system

- WCS – Wort cooling system – equipment for controlled hot wort cooling to the fermentation temperature (7°C or 25°C depending on the type of beer)

- MMG – Malt mill – equipment for grinding of malt – necessary only for production of wort from malt (not necessary for production of wort from malt extract)

- LEA – Laboratory equipment and accessories – saccharimeters, alcoholmeters, graduated cylinder, wooden rod for manual level measurement

- HWT – Heat water tank – insulated vessel for storaging of heat water purchased from wort cooling process. It is necessary to have hot water available for some parts of boiling cycle in the brewhouse.

- ITWT – Ice treated water tank – insulated vessel for cooling, storaging and pumping of ice water which is necessary in wort cooling process. This treated drinking ice water is heated in wort cooling process and becomes then hot water storaged in HWT. If is not available drinking water with requested chemical composition, it is needed to use some equipment for water treatment – WTS. Available for breweries with one-level wort cooling system – we recomment it for brewhouses with production capacity above 1000 liters of wort per one brew instead ICWT.

- ICWT – Ice cooling water tank – insulated vessel for cooling, storaging and pumping of ice water which is necessary in wort cooling process. This treated drinking ice water is heated in wort cooling process and then is comming back to the cooling system. Available for breweries with two-level wort cooling system – we recomment it for brewhouses with production capacity max.1000 liters of wort per one brew instead ITWT.

- WTS – Water treatment systems – equipment for treating of cold water that has not requested chemical composition available for brewing of choosed type beer. It is needed a chemical analysis for assessment of suitable water chemical composition.

Recommended accessories for the brewhouses BREWORX CLASSIC

Automatic control system for the BREWORX CLASSIC wort brew machines

- BHAC-1C : Brewhouse Breworx Automatic Control System with customization

The BHAC1 is automatic control system for brewhouse with computer support and most operations controlled automatically - according to a specified program from a central control panel. This control system cooperates with our brewhouses Breworx Classic, Breworx Lite-ME and Breworx Tritank with usable volumes from 150 to 1000 liters. This version is calculated for a customization of standard version of BHAC1 system according to special customer´s requirements. Read more »

The BHAC1 is automatic control system for brewhouse with computer support and most operations controlled automatically - according to a specified program from a central control panel. This control system cooperates with our brewhouses Breworx Classic, Breworx Lite-ME and Breworx Tritank with usable volumes from 150 to 1000 liters. This version is calculated for a customization of standard version of BHAC1 system according to special customer´s requirements. Read more » - BHAC-6C Brewhouse Oppidum Automatic Control System with customization

The BHAC3 is an automatic control system for the OPPIDUM wort preparation machines with computer support and most operations controlled automatically – according to a specified program from a central control panel. This control system cooperates with OPPIDUM machines with usable production volumes from 1000 up to 5000 liters of wort per one batch. This version is calculated for a customization of standard version of BHAC3 system according to special customer´s requirements. BHAC3C - the automatic control system for the wort production machine OPPIDUM includes: Automatically controlled hot process of brewing – fully automatized management of the entire processes of… Read more »

The BHAC3 is an automatic control system for the OPPIDUM wort preparation machines with computer support and most operations controlled automatically – according to a specified program from a central control panel. This control system cooperates with OPPIDUM machines with usable production volumes from 1000 up to 5000 liters of wort per one batch. This version is calculated for a customization of standard version of BHAC3 system according to special customer´s requirements. BHAC3C - the automatic control system for the wort production machine OPPIDUM includes: Automatically controlled hot process of brewing – fully automatized management of the entire processes of… Read more » - BHAC-4 Automatic Control System for brewhouses Quadrant 1000L-5000L

The BHAC4 is automatic control system for brewhouse with computer support and most operations controlled automatically - according to a specified program from a central control panel. This control system cooperates with our brewhouses QUADRANT with usable volumes from 1000 to 5000 liters. Read more »

The BHAC4 is automatic control system for brewhouse with computer support and most operations controlled automatically - according to a specified program from a central control panel. This control system cooperates with our brewhouses QUADRANT with usable volumes from 1000 to 5000 liters. Read more » - BHSA-1 : Semi-Automatic Control System for brewhouses Classic, Lite-ME, Tritank 150L-1000L (with complete control via touch LCD)

The semi-automatic control system with complete control via touch LCD for the brewhouses Breworx Classic, Lite-ME, Tritank 150L-1000L (upgradeable to the fully automatic system). All valves are controlleable via the touch LCD panel, several operations are controlled automatically - according to a specified program. This control system cooperates with our brewhouses Breworx Classic, Breworx Lite-ME and Breworx Tritank with nominal volumes from 150 to 1000 liters. The semi-automation of the brewing machine is supplied as part of the brewhouse, but is not included in its basic price. Read more »

The semi-automatic control system with complete control via touch LCD for the brewhouses Breworx Classic, Lite-ME, Tritank 150L-1000L (upgradeable to the fully automatic system). All valves are controlleable via the touch LCD panel, several operations are controlled automatically - according to a specified program. This control system cooperates with our brewhouses Breworx Classic, Breworx Lite-ME and Breworx Tritank with nominal volumes from 150 to 1000 liters. The semi-automation of the brewing machine is supplied as part of the brewhouse, but is not included in its basic price. Read more » - BHSA-2 : Semi-Automatic Control System for brewhouses Classic, Lite-ME, Tritank 1200L-5000L (with complete control via touch LCD)

The semi-automatic control system with complete control via touch LCD for the brewhouses Breworx Classic, Lite-ME, Tritank 1200L-5000L (upgradeable to the fully automatic system). All valves are controlleable via the touch LCD panel, several operations are controlled automatically - according to a specified program. This control system cooperates with our brewhouses Breworx Classic, Breworx Lite-ME and Breworx Tritank with nominal volumes from 1200 to 5000 liters. The semi-automation of the brewing machine is supplied as part of the brewhouse, but is not included in its basic price. Read more »

The semi-automatic control system with complete control via touch LCD for the brewhouses Breworx Classic, Lite-ME, Tritank 1200L-5000L (upgradeable to the fully automatic system). All valves are controlleable via the touch LCD panel, several operations are controlled automatically - according to a specified program. This control system cooperates with our brewhouses Breworx Classic, Breworx Lite-ME and Breworx Tritank with nominal volumes from 1200 to 5000 liters. The semi-automation of the brewing machine is supplied as part of the brewhouse, but is not included in its basic price. Read more »

Electric steam generators

- MESG-15S : Micro electric steam generator 15kW 0.5bar (20 kg/h)

Powerful steam generator with heating capacity of 15 kW for extra heavy continuous load operation. These robust models in a stainless steel case have exceptional steam generating capabilities thanks to the unique Teflon technology on the heating spirals. Output capacity is up to 20 kg of steam per hour at pressure 0.5 bar and temperature 111°C. Read more »

Powerful steam generator with heating capacity of 15 kW for extra heavy continuous load operation. These robust models in a stainless steel case have exceptional steam generating capabilities thanks to the unique Teflon technology on the heating spirals. Output capacity is up to 20 kg of steam per hour at pressure 0.5 bar and temperature 111°C. Read more » - MESG-18S : Micro electric steam generator 18kW 0.5bar (24 kg/h)

Powerful steam generator with heating capacity of 18 kW for extra heavy continuous load operation. These robust models in a stainless steel case have exceptional steam generating capabilities thanks to the unique Teflon technology on the heating spirals. Output capacity is up to 24 kg of steam per hour at pressure 0.5 bar and temperature 111°C. Read more »

Powerful steam generator with heating capacity of 18 kW for extra heavy continuous load operation. These robust models in a stainless steel case have exceptional steam generating capabilities thanks to the unique Teflon technology on the heating spirals. Output capacity is up to 24 kg of steam per hour at pressure 0.5 bar and temperature 111°C. Read more » - MOSG-12E : Mobile electric steam generator 12 kW | 18 kg/hr | 0.7 bar

The mobile steam generator with the heating capacity of 12kW is conceived for the production of hot steam which is needed for cleansing and steam sterilisation of stainless steel tanks, barrels, pipe systemsand fittings, filters and beverage filling units. Maximal operation pressure of steam is 0.7 bar (temperature of 115°C) . Production capacity is approximaly 18 kg of steam per hour. The steam production unit is made of stainless steel. Read more »

The mobile steam generator with the heating capacity of 12kW is conceived for the production of hot steam which is needed for cleansing and steam sterilisation of stainless steel tanks, barrels, pipe systemsand fittings, filters and beverage filling units. Maximal operation pressure of steam is 0.7 bar (temperature of 115°C) . Production capacity is approximaly 18 kg of steam per hour. The steam production unit is made of stainless steel. Read more » - MOSG-18E : Mobile electric steam generator 18 kW | 27 kg/hr | 0.7 bar

The mobile steam generator with the heating capacity of 18kW is conceived for the production of hot steam which is needed for cleansing and steam sterilisation of stainless steel tanks, barrels, pipe systemsand fittings, filters and beverage filling units. Maximal operation pressure of steam is 0.7 bar (temperature of 115°C) . Production capacity is approximaly 27 kg of steam per hour. The steam production unit is made of stainless steel. Read more »

The mobile steam generator with the heating capacity of 18kW is conceived for the production of hot steam which is needed for cleansing and steam sterilisation of stainless steel tanks, barrels, pipe systemsand fittings, filters and beverage filling units. Maximal operation pressure of steam is 0.7 bar (temperature of 115°C) . Production capacity is approximaly 27 kg of steam per hour. The steam production unit is made of stainless steel. Read more » - MOSG-24E : Mobile electric steam generator 24 kW | 36 kg/hr | 0.7 bar

The mobile steam generator with the heating capacity of 24kW is conceived for the production of hot steam which is needed for cleansing and steam sterilisation of stainless steel tanks, barrels, pipe systemsand fittings, filters and beverage filling units. Maximal operation pressure of steam is 0.7 bar (temperature of 115°C) . Production capacity is approximaly 36 kg of steam per hour. The steam production unit is made of stainless steel. Read more »

The mobile steam generator with the heating capacity of 24kW is conceived for the production of hot steam which is needed for cleansing and steam sterilisation of stainless steel tanks, barrels, pipe systemsand fittings, filters and beverage filling units. Maximal operation pressure of steam is 0.7 bar (temperature of 115°C) . Production capacity is approximaly 36 kg of steam per hour. The steam production unit is made of stainless steel. Read more »

Gas steam generators

- GSG-500A5S : Gas steam generator ALBA D05-500 350 kW | 500kg/hr | 12-16bar | Complete steam boiler room on the frame

The compact fully equipped steam boiler room based on the ALBA D05-500 gas steam generator with output capacity 350 kW which generates up to 500 kg of hot steam per hour at pressure of up to 12-16 bar (according to required version). The compact solution of a complete system which which includes the steam generator, the water/condensate supply tank, the water treatment system, the circulation pump, the by-pass system, all internal pipelines, electric switchbox and connections and all other necessary elements. The pre-installed compact system occupies less floor space, saves your time and money needed for the installation work. Its… Read more »

The compact fully equipped steam boiler room based on the ALBA D05-500 gas steam generator with output capacity 350 kW which generates up to 500 kg of hot steam per hour at pressure of up to 12-16 bar (according to required version). The compact solution of a complete system which which includes the steam generator, the water/condensate supply tank, the water treatment system, the circulation pump, the by-pass system, all internal pipelines, electric switchbox and connections and all other necessary elements. The pre-installed compact system occupies less floor space, saves your time and money needed for the installation work. Its… Read more » - GSG-750A5S : Gas steam generator ALBA D05-750 524 kW | 750kg/hr | 12-16bar | Complete steam boiler room on the frame

The compact fully equipped steam boiler room based on the ALBA D05-750 gas steam generator with output capacity 524 kW which generates up to 750 kg of hot steam per hour at pressure of up to 12-16 bar (according to required version). The compact solution of a complete system which which includes the steam generator, the water/condensate supply tank, the water treatment system, the circulation pump, the by-pass system, all internal pipelines, electric switchbox and connections and all other necessary elements. The pre-installed compact system occupies less floor space, saves your time and money needed for the installation work. Its… Read more »

The compact fully equipped steam boiler room based on the ALBA D05-750 gas steam generator with output capacity 524 kW which generates up to 750 kg of hot steam per hour at pressure of up to 12-16 bar (according to required version). The compact solution of a complete system which which includes the steam generator, the water/condensate supply tank, the water treatment system, the circulation pump, the by-pass system, all internal pipelines, electric switchbox and connections and all other necessary elements. The pre-installed compact system occupies less floor space, saves your time and money needed for the installation work. Its… Read more » - GSG-1000A5S : Gas steam generator ALBA D05-1000 700 kW | 1000kg/hr | 12-16bar | Complete steam boiler room on the frame

The compact fully equipped steam boiler room based on the ALBA D05-1000 gas steam generator with output capacity 700 kW which generates up to 1000 kg of hot steam per hour at pressure of up to 12-16 bar (according to required version). The compact solution of a complete system which which includes the steam generator, the water/condensate supply tank, the water treatment system, the circulation pump, the by-pass system, all internal pipelines, electric switchbox and connections and all other necessary elements. The pre-installed compact system occupies less floor space, saves your time and money needed for the installation work. Its… Read more »

The compact fully equipped steam boiler room based on the ALBA D05-1000 gas steam generator with output capacity 700 kW which generates up to 1000 kg of hot steam per hour at pressure of up to 12-16 bar (according to required version). The compact solution of a complete system which which includes the steam generator, the water/condensate supply tank, the water treatment system, the circulation pump, the by-pass system, all internal pipelines, electric switchbox and connections and all other necessary elements. The pre-installed compact system occupies less floor space, saves your time and money needed for the installation work. Its… Read more » - GSG-1500A5S : Gas steam generator ALBA D05-1500 1048 kW | 1500kg/hr | 12-16bar | Complete steam boiler room on the frame

The compact fully equipped steam boiler room based on the ALBA D05-1500 gas steam generator with output capacity 1048 kW which generates up to 1500 kg of hot steam per hour at pressure of up to 12-16 bar (according to required version). The compact solution of a complete system which which includes the steam generator, the water/condensate supply tank, the water treatment system, the circulation pump, the by-pass system, all internal pipelines, electric switchbox and connections and all other necessary elements. The pre-installed compact system occupies less floor space, saves your time and money needed for the installation work. Its… Read more »

The compact fully equipped steam boiler room based on the ALBA D05-1500 gas steam generator with output capacity 1048 kW which generates up to 1500 kg of hot steam per hour at pressure of up to 12-16 bar (according to required version). The compact solution of a complete system which which includes the steam generator, the water/condensate supply tank, the water treatment system, the circulation pump, the by-pass system, all internal pipelines, electric switchbox and connections and all other necessary elements. The pre-installed compact system occupies less floor space, saves your time and money needed for the installation work. Its… Read more » - GSG-2000A5S : Gas steam generator ALBA D05-2000 1397 kW | 2000kg/hr | 12-16bar | Complete steam boiler room on the frame

The compact fully equipped steam boiler room based on the ALBA D05-2000 gas steam generator with output capacity 1397 kW which generates up to 2000 kg of hot steam per hour at pressure of up to 12-16 bar (according to required version). The compact solution of a complete system which which includes the steam generator, the water/condensate supply tank, the water treatment system, the circulation pump, the by-pass system, all internal pipelines, electric switchbox and connections and all other necessary elements. The pre-installed compact system occupies less floor space, saves your time and money needed for the installation work. Its… Read more »

The compact fully equipped steam boiler room based on the ALBA D05-2000 gas steam generator with output capacity 1397 kW which generates up to 2000 kg of hot steam per hour at pressure of up to 12-16 bar (according to required version). The compact solution of a complete system which which includes the steam generator, the water/condensate supply tank, the water treatment system, the circulation pump, the by-pass system, all internal pipelines, electric switchbox and connections and all other necessary elements. The pre-installed compact system occupies less floor space, saves your time and money needed for the installation work. Its… Read more »

Screw conveyors

- SCR-80 : Screw conveyor 8m

Optional equipment for a brewery - the grist screw conveyor, which transports the malt to the grist hopper on the mashing tank of the brewhouse. 8 meters length. Read more »

Optional equipment for a brewery - the grist screw conveyor, which transports the malt to the grist hopper on the mashing tank of the brewhouse. 8 meters length. Read more » - SCR-100 : Screw conveyor 10 m

Optional equipment for a brewery - the grist screw conveyor, which transports the malt to the grist hopper on the mashing tank of the brewhouse. 10 meters length. Read more »

Optional equipment for a brewery - the grist screw conveyor, which transports the malt to the grist hopper on the mashing tank of the brewhouse. 10 meters length. Read more » - SCR-RED Reductor – Adapting the screw conveyor to a particular malt crusher

The optional equipment for the screw conveyor and the malt crusher. A reduction produced of stainless steel sheet between a screw conveyor and a malt crusher. We recommend to use this reductor to avoid excessive dusting as well as grain losses during malt crushing. We design, produce and customize the reductor individualy according to choosed type of the screw conveyor and malt crusher. Read more »

The optional equipment for the screw conveyor and the malt crusher. A reduction produced of stainless steel sheet between a screw conveyor and a malt crusher. We recommend to use this reductor to avoid excessive dusting as well as grain losses during malt crushing. We design, produce and customize the reductor individualy according to choosed type of the screw conveyor and malt crusher. Read more » - SCRV-23 : Screw conveyor 2300mm with the vibrating hopper 9m3/h

Inclined screw conveyor with a vibrating hopper 150l/min is a device for continuous inclined (rising) movement of bulk material with a discharge height of 2 m above the ground. The material is moved up from the hopper using a worm shaft, which rotates to move the material from the hopper to the outlet. This type of conveyor is suitable for all bulk materials or granules (malt, malt grist) up to a diameter of 10 mm. Read more »

Inclined screw conveyor with a vibrating hopper 150l/min is a device for continuous inclined (rising) movement of bulk material with a discharge height of 2 m above the ground. The material is moved up from the hopper using a worm shaft, which rotates to move the material from the hopper to the outlet. This type of conveyor is suitable for all bulk materials or granules (malt, malt grist) up to a diameter of 10 mm. Read more » - MDW-100 : Malt dispenser 0.10-100kg with weighing hopper 70L

Industrial batcher for bulk materials and mixtures with weighing of precisely specified weight in any range from 100g - 10000g. The weighed dose can be set with a resolution of up to 1g. Read more »

Industrial batcher for bulk materials and mixtures with weighing of precisely specified weight in any range from 100g - 10000g. The weighed dose can be set with a resolution of up to 1g. Read more »